Page 180 - dyc

P. 180

Technical Data

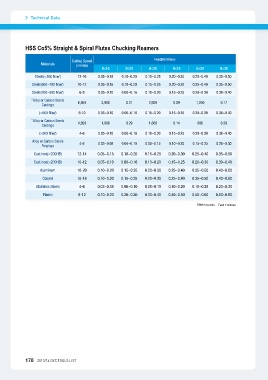

HSS Co5% Straight & Spiral Flutes Chucking Reamers

Cutiing Speed Feed(mm/rev.)

(m/min)

Materials Ø≤10 Ø≤20 Ø≤30 Ø≤10 Ø≤20 Ø≤30

12-16 0.05~0.15 0.10~0.20 0.15~0.25 0.20~0.30 0.25~0.40 0.35~0.50

Steels(<500 N/㎟) 10-12 0.05~0.15 0.10~0.20 0.15~0.25 0.20~0.30 0.25~0.40 0.35~0.50

Steels(500~700 N/㎟) 6-8 0.05~0.10 0.08~0.16 0.10~0.20 0.15~0.25 0.20~0.30 0.30~0.40

Steels(700~800 N/㎟)

"Alloy or Carbon Steels 6,500 3,900 0.21 2,600 0.09 1,200 0.17

Castings 6-10 0.05~0.10 0.08~0.16 0.10~0.20 0.15~0.25 0.20~0.30 0.30~0.40

(<500 N/㎟)

"Alloy or Carbon Steels 4,200 1,800 0.29 1,600 0.14 800 0.26

Castings 4-6 0.05~0.10 0.08~0.16 0.10~0.20 0.15~0.25 0.20~0.30 0.30~0.40

(>500 N/㎟)

Alloy or Carbon Steels 4-6 0.03~0.08 0.06~0.10 0.08~0.15 0.10~0.20 0.15~0.25 0.20~0.30

Forgings 12-14 0.05~0.15 0.10~0.20 0.15~0.25 0.20~0.30 0.25~0.40 0.35~0.50

Cast Iron(<200HB) 10-12 0.05~0.10 0.08~0.16 0.10~0.20 0.15~0.25 0.20~0.30 0.30~0.40

Cast Iron(>200HB) 16-20 0.10~0.20 0.15~0.25 0.20~0.30 0.25~0.40 0.35~0.50 0.40~0.60

16-18 0.10~0.20 0.15~0.25 0.20~0.30 0.25~0.40 0.35~0.50 0.40~0.60

Aluminum 4-6 0.03~0.08 0.06~0.10 0.08~0.15 0.10~0.20 0.15~0.25 0.20~0.30

Cooper 8-12 0.10~0.20 0.20~0.30 0.30~0.40 0.40~0.50 0.50~0.60 0.60~0.80

Stainless Steels

Plastic

RPM = rev./min. Feed = min/rev.

178 2013/14 DYC TOOLS LIST