Page 175 - dyc

P. 175

Technical Data

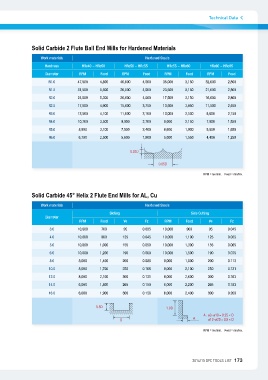

Solid Carbide 2 Flute Ball End Mills for Hardened Materials

Work materials Hardened Steels

Hardness

Diameter HRc40 ~ HRc50 HRc50 ~ HRc55 HRc55 ~ HRc60 HRc60 ~ HRc65

R1.0

R1.5 RPM Feed RPM Feed RPM Feed RPM Feed

R2.0

R2.5 47,500 4,800 40,000 4,000 35,000 3,150 32,000 2,800

R3.0

R4.0 31,500 5,300 26,500 4,000 23,500 3,150 21,000 2,800

R5.0

R6.0 24,000 5,300 20,000 4,000 17,500 3,150 16,000 2,800

17,500 4,900 15,000 3,750 13,500 3,050 11,500 2,550

13,500 4,100 11,000 3,100 10,000 2,500 8,800 2,150

10,700 3,500 9,000 2,700 8,000 2,150 7,000 1,850

8,900 3,100 7,500 2,400 6,600 1,900 5,800 1,650

6,700 2,500 5,600 1,900 5,000 1,550 4,400 1,250

0.02D

0.05D

RPM = rev./min. Feed = min/rev.

Solid Carbide 45° Helix 2 Flute End Mills for AL, Cu

Work materials Hardened Steels

Diameter Sloting Side Cutting

3.0 RPM Feed Ve Fz RPM Feed Ve Fz

4.0 10,000 0.035 10,000 0.045

5.0 10,000 700 95 0.045 10,000 900 95 0.055

6.0 10,000 0.050 10,000 0.065

8.0 10,000 900 125 0.060 10,000 1,100 125 0.075

10.0 8,000 0.088 8,000 0.113

12.0 8,000 1,000 155 0.106 8,000 1,300 155 0.131

14.0 8,000 0.131 8,000 0.163

16.0 6,000 1,200 190 0.150 6,000 1,500 190 0.183

6,000 0.158 6,000 0.200

1,400 200 1,800 200

1,700 250 2,100 250

2,100 300 2,600 300

1,800 265 2,200 265

1,900 300 2,400 300

0.5D 1.0D

D

A A : ø3~ø10 = 0.25 × D

ø12~ø20 = 0.5 × D

RPM = rev./min. Feed = min/rev.

2014/15 DYC TOOLS LIST 173