Page 173 - dyc

P. 173

Technical Data

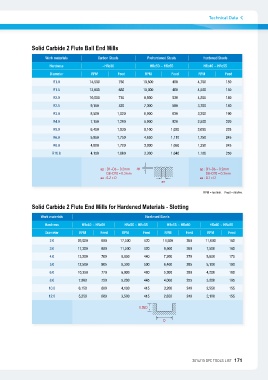

Solid Carbide 2 Flute Ball End Mills

Work materials Carbon Steels Prehardened Steels Hardened Steels

Hardness

Diameter ~HRc30 HRc50 ~ HRc55 HRc45 ~ HRc55

R1.0

R1.5 RPM Feed RPM Feed RPM Feed

R2.0

R2.5 14,500 750 10,500 490 4,700 150

R3.0

R4.0 13,000 680 10,000 460 4,500 150

R5.0

R6.0 10,500 740 8,500 530 4,200 180

R8.0

R10.0 9,150 820 7,300 580 3,700 180

8,500 1,020 6,900 830 3,200 190

7,150 1,290 5,800 920 2,500 220

6,400 1,530 5,100 1,020 2,050 225

5,850 1,750 4,650 1,110 1,750 245

4,800 1,720 3,800 1,060 1,350 245

4,150 1,660 3,300 1,040 1,100 250

ap : D1~D6 = 0.2mm ap ap : D1~D6 = 0.2mm

D8~D20 = 0.3mm D8~D20 = 0.3mm

ae

ae : 0.2 × D ae : 0.1 × D

RPM = rev./min. Feed = min/rev.

Solid Carbide 2 Flute End Mills for Hardened Materials - Slotting

Work materials Hardened Steels

Hardness

Diameter HRc40 ~ HRc50 HRc50 ~ HRc55 HRc55 ~ HRc60 HRc60 ~ HRc65

2.0

3.0 RPM Feed RPM Feed RPM Feed RPM Feed

4.0

5.0 26,000 680 17,500 420 14,500 260 11,000 160

6.0

8.0 17,300 680 11,500 420 9,500 260 7,500 160

10.0

12.0 13,200 700 8,800 440 7,200 270 5,600 170

12,500 805 8,300 500 6,400 285 5,100 180

10,350 770 6,900 480 5,300 280 4,200 180

7,800 720 5,200 445 4,000 255 3,200 165

6,150 680 4,100 415 3,200 240 2,550 155

5,250 680 3,500 415 2,650 240 2,100 155

0.05D

D

2014/15 DYC TOOLS LIST 171