Page 177 - dyc

P. 177

Technical Data

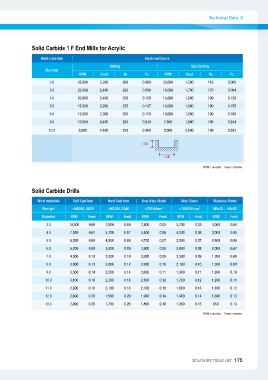

Solid Carbide 1 F End Mills for Acrylic

Work materials Hardened Steels

Diameter Sloting Side Cutting

2.0 RPM Feed Ve Fz RPM Feed Ve Fz

3.0 32,000 0.069 23,000 0.065

4.0 25,000 2,200 200 0.096 18,000 1,500 145 0.094

5.0 20,000 0.120 15,000 0.120

6.0 15,000 2,400 235 0.147 12,000 1,700 170 0.150

8.0 13,500 0.170 10,000 0.180

10.0 10,000 2,400 250 0.240 7,800 1,800 190 0.244

8,000 0.300 8,000 0.333

2,200 235 1,800 190

1.5D 1.0D

2,300 255 1,800 190

2,400 250 1,900 195

2,400 250 2,000 190

RPM = rev./min. Feed = min/rev.

Solid Carbide Drills

Work materials Soft Cast Iron Hard Cast Iron Non-Alloy Steels Alloy Steels Stainless Steels

Strength

Diameter <HB240, GG25 <HB300, GG40 <700 N/mm2 <1000 N/mm2 HRc45 ~ HRc55

3.0

4.0 RPM Feed RPM Feed RPM Feed RPM Feed RPM Feed

5.0

6.0 10,500 0.06 7,600 0.06 7,800 0.05 5,700 0.05 4,000 0.04

7.0

8.0 7,800 0.07 5,700 0.07 5,800 0.06 4,300 0.06 3,000 0.05

9.0

10.0 6,200 0.08 4,500 0.08 4,700 0.07 3,500 0.07 2,400 0.06

11.0

12.0 5,200 0.09 3,800 0.09 3,900 0.08 2,800 0.08 2,000 0.07

13.0

4,500 0.10 3,300 0.10 3,300 0.09 2,500 0.09 1,700 0.08

3,900 0.12 2,800 0.12 2,900 0.10 2,100 0.10 1,500 0.09

3,500 0.14 2,500 0.14 2,600 0.11 1,900 0.11 1,300 0.10

3,100 0.16 2,300 0.16 2,300 0.12 1,700 0.12 1,200 0.11

2,800 0.18 2,100 0.18 2,100 0.13 1,600 0.13 1,100 0.12

2,600 0.20 1,900 0.20 1,900 0.14 1,400 0.14 1,000 0.13

2,400 0.20 1,700 0.20 1,800 0.16 1,300 0.16 950 0.13

RPM = rev./min. Feed = min/rev.

2014/15 DYC TOOLS LIST 175