Page 38 - bpk_brill

P. 38

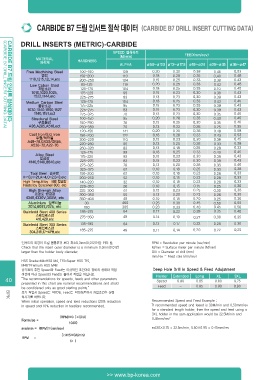

CARBIDE B7 드릴 인서트 절삭 데이터 (CARBIDE B7 DRILL INSERT CUTTING DATA)

CARBIDE B7 드릴 인서트 절삭데이타 DRILL INSERTS (METRIC)-CARBIDE

(CARBIDE B7 DRILL INSERT CUTTING DATA) MATERIAL SPEED 절삭속도 FEED(mm/rev)

피삭재 (M/min)

HARDNESS ALPHA ø9.5~ø12.5 ø13~ø17.5 ø18~ø24 ø25~ø35 ø36~ø47

Free Machining Steel 100-150 128 0.20 0.30 0.38 0.45 0.53

연강 150-200 110 0.18 0.28 0.35 0.40 0.48

200-250 104 0.15 0.25 0.33 0.38 0.43

1118,1215,12L14,etc 85-125 119 0.20 0.25 0.33 0.43 0.48

Low Cabon Steel 125-175 104 0.18 0.25 0.33 0.10 0.45

175-225 95 0.15 0.23 0.30 0.38 0.43

저탄소강 225-275 83 0.13 0.23 0.30 0.38 0.43

1010,1020,1025, 125-175 104 0.18 0.25 0.33 0.43 0.45

175-225 95 0.15 0.23 0.33 0.38 0.43

1522,1144,etc 225-275 83 0.15 0.23 0.30 0.38 0.43

Medium Carbon Steel 275-325 70 0.13 0.23 0.30 0.35 0.40

100-150 95 0.20 0.28 0.35 0.40 0.45

중탄소강 150-250 76 0.15 0.25 0.30 0.35 0.40

1030,1040,1050,1527 250-350 70 0.13 0.23 0.28 0.25 0.35

120-150 141 0.20 0.30 0.38 0.48 0.58

1140,1151,ect 150-200 122 0.18 0.28 0.33 0.43 0.53

Structural Steel 200-220 110 0.15 0.23 0.30 0.38 0.45

220-260 95 0.13 0.20 0.28 0.33 0.38

구조용강 260-320 83 0.13 0.18 0.25 0.28 0.33

A36,A285,A516,ect 125-175 99 0.18 0.25 0.33 0.40 0.45

175-225 92 0.15 0.23 0.30 0.38 0.43

Cast Iron/S,G Iron 225-275 83 0.15 0.23 0.30 0.38 0.43

주철/덕타일 275-325 76 0.13 0.20 0.28 0.35 0.40

325-375 67 0.10 0.18 0.25 0.33 0.38

A48-76,GR30/GR45, 150-200 67 0.10 0.18 0.23 0.28 0.33

A536-72,A22-76 200-250 52 0.10 0.15 0.23 0.28 0.33

140-220 32 0.10 0.18 0.23 0.28 0.33

Alloy Steel 220-310 26 0.10 0.15 0.15 0.25 0.30

합금강 225-300 61 0.15 0.23 0.25 0.30 0.38

300-350 55 0.13 0.20 0.23 0.28 0.35

4140,5140,8640,etc 350-400 49 0.10 0.18 0.20 0.25 0.30

460 0.25 0.38 0.45 0.50 0.55

Tool Steel 공구강 30 305 0.23 0.33 0.40 0.45 0.50

H-13,H-21,A-4,O-2,S-3,etc 180 64 0.17 0.22 0.29 0.35 0.40

High Temp.Alloy 내열 합금강 185-275 49 0.14 0.19 0.27 0.30 0.35

Hastelloy B,Inconel 600, etc 275-350

64 0.13 0.17 0.22 0.26 0.30

High Strengh Alloy 135-185 49

고경도 합금강 185-275 0.11 0.14 0.20 0.22 0.25

4340,4330V,300M, etc

Aluminium 알루미늄

2014,6061,7075, etc

Stainledd Steet 400 Series

스테인레스강

416,420,etc

Stainledd Steet 300 Series

스테인레스강

304,316,17-4PH,etc

인서트의 외경이 드릴 몸통부위 보다 최소0.3mm(0.012)이상 커야 함. RPM = Revolution per minute (rev/min)

Check that the insert outer diameter is a minimum 0.3mm(0.012″) M/mm = Surface meter per minute (M/min)

larger than the holder body diameter. DIA = Diameter of drill (mm)

mm/rev = Feed rate (mm/rev)

HSS Grade=M4=HSS M4, T15=Super HSS T15,

M48=Premium HSS M48 Deep Hole Drill in Speed & Feed Adujstment

상기표의 추천 Speed와 Feed는 이상적인 조건이며 장비의 상태와 작업

40 여건에 따라 Speed와 Feed는 줄여서 작업을 하십시오. Holder Extended Long XL 3XL

“The recommendations for speeds, feeds and other parameters Speed 0.90 0.85 0.80 0.75

presented in this chart are nominal recommendations and shold

be condidered only as good starting points.” Feed - 0.95 0.90 0.90

초기 작업시 Speed는 약20%, Feed는 약10%줄여서 자업조건을 설정

하시기를 바랍니다. Recommended Speed and Feed Example :

When initial operation, speed and feed reductions (20% reduction “If recommended speed and feeed is 30M/min and 0.50mm/rev

in speed and 10% reduction in feed)are recommended.

for a standard length holder, then the speed and feed using a

Formulas = (RPM)×(π)×(DIA) 3XL holder in the sam application would be 22.5M/min and

1000 0.45mm/rev”

mm/min = (RPM)×(mm/rev) ex)30×0.75 = 22.5m/min, 0.50×0.90 = 0.45mm/rev

RPM = 3.1415×(M/min)

(π)

>> www.bp-korea.com