Page 213 - jjtools

P. 213

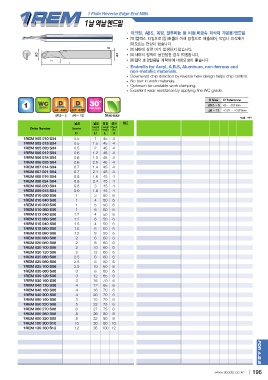

1 Flute Reverse Edge End Mills

1

0 0.01 0.01 0.025 Endmills for Acryl, A.B.S, Aluminum, non-ferrous and

non-metallic materials.

0.5 ~ 6 ~ 12 Sharp Edge Downward chip direction by reverse helix design helps chip control.

No burr in work materials.

Optimum for unstable work clamping.

Excellent wear resistance by applying fine WC grade.

D Size D Tolerance

0.5 ~ 5 +0 ~ -0.01mm

6 ~ 12 -0.01 ~ -0.025mm

mm

Order Number Diameter Length Overall Shank

of cut Length Dia

1REM 005 010 S04 D L1 L d

1REM 005 015 S04

1REM 005 020 S04 0.5 1 45 4

1REM 006 012 S04 0.5 1.5 45 4

1REM 006 018 S04 0.5 2 45 4

1REM 006 025 S04 0.6 1.2 45 4

1REM 007 014 S04 0.6 1.8 45 4

1REM 007 021 S04 0.6 2.5 45 4

1REM 008 016 S04 0.7 1.4 45 4

1REM 008 024 S04 0.7 2.1 45 4

1REM 008 030 S04 0.8 1.6 45 4

1REM 009 018 S04 0.8 2.4 45 4

1REM 010 030 S06 0.8 3 45 4

1REM 010 040 S06 0.9 1.8 45 4

1REM 010 050 S06 1 3 50 6

1REM 010 060 S06 1 4 50 6

1REM 012 040 S06 1 5 50 6

1REM 012 060 S06 1 6 60 6

1REM 015 040 S06 1.2 4 50 6

1REM 015 060 S06 1.2 6 50 6

1REM 015 080 S06 1.5 4 50 6

1REM 020 060 S06 1.5 6 50 6

1REM 020 080 S06 1.5 8 50 6

1REM 020 100 S06 2 6 60 6

1REM 020 120 S06 2 8 60 6

1REM 025 060 S06 2 10 60 6

1REM 025 080 S06 2 12 60 6

1REM 025 100 S06 2.5 6 60 6

1REM 030 080 S06 2.5 8 60 6

1REM 030 120 S06 2.5 10 60 6

1REM 030 160 S06 3 8 60 6

1REM 040 120 S06 3 12 65 6

1REM 040 160 S06 3 16 70 6

1REM 040 200 S06 4 12 65 6

1REM 050 150 S06 4 16 70 6

1REM 050 220 S06 4 20 70 6

1REM 060 270 S06 5 15 70 6

1REM 080 260 S08 5 22 75 6

1REM 080 320 S08 6 27 75 6

1REM 100 300 S10 8 26 80 8

1REM 120 350 S12 8 32 90 8

10 30 90 10

12 35 100 12

FOR A.B.S

www.jjtools.co.kr 196