Page 272 - jjtools

P. 272

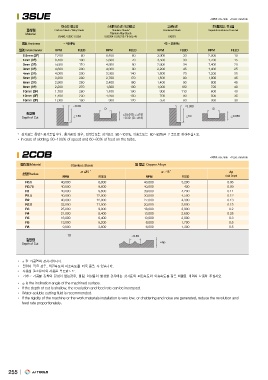

3SUE RPM : rev./min Feed : mm/min

Superhit resistance / Inconel

Carbon Steels / Alloy Steels Stainless Steels/ Hardened Steels

Titanium Alloy Steels

Material SS400 / S50C / SCM SUS304 / SUS316 / Ti-6AL-4V SKD61

Hardness ~ 45HRc 45 ~ 55HRc

Outside Diameter RPM FEED RPM FEED RPM FEED RPM FEED

0.8mm (3F) 10

1mm (3F) 7,200 80 6,400 60 3,900 30 2,000 15

2mm (3F) 6,400 100 5,600 70 3,500 30 1,700 20

3mm (3F) 5,600 110 4,800 80 2,900 34 1,400 25

4mm (3F) 4,800 200 4,000 90 2,200 45 1,400 35

5mm (3F) 4,000 200 3,300 140 1,800 70 1,200 45

6mm (3F) 3,200 230 2,700 170 1,500 90 1,000 45

8mm (3F) 2,900 250 2,400 180 1,400 90 40

10mm (3F) 2,200 270 1,800 190 1,000 100 900 40

12mm (3F) 1,700 260 1,400 190 110 720 35

16mm (3F) 1,400 230 1,200 150 900 90 600 30

1,000 160 120 700 60 500

Depth of Cut 900 550 360 0.05D

0.2D 0.05D

1.5D 0.5D (D 18) 1D

0.3D (D 18)

In case of slotting, 80~100% of speed and 60~80% of feed on the talbe.

2COB Stainless Steels Copper Alloys RPM : rev./min Feed : mm/min

Material 15 15 Ap

FEED

Radius RPM RPM FEED Axial Depth

8,000

R0.5 40,000 9,600 40,000 3,200 0.06

R0.75 40,000 9,600 40,000 400 0.09

R1 40,000 12,000 39,000 0.11

R1.5 40,000 12,000 30,000 4,700 0.12

R2 40,000 11,000 27,000 4,500 0.13

R2.5 32,000 9,000 20,000 4,300 0.15

R3 25,000 8,400 16,000 3,600

R4 21,000 6,400 13,000 2,900 0.2

R5 16,000 5,200 10,000 2,600 0.25

R6 13,000 3,600 2,000

R8 8,000 1,700 0.3

9,000 6,000 1,300 0.5

0.5

Depth of Cut 0.2R

Ap

is the inclination angle of the machined surface.

If the depth of cut is shallow, the revolution and feed rate can be increased.

Water-soluble cutting fluid is recommended.

If the rigidity of the machine or the work materials installation is very low, or chattering and noise are generated, reduce the revolution and

feed rate proportionately.

255 JJ TOOLS