Page 27 - samyoung

P. 27

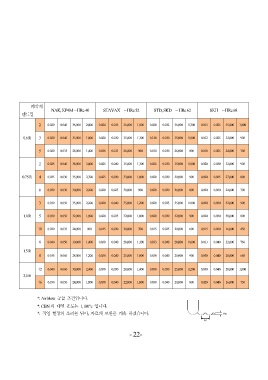

피삭재 NAK, KP4M ~ HRc 40 STAVAX ~ HRc 52 STD, SKD ~ HRc 62 SKH ~ HRc 68

엔드밀

2 0.020 0.040 36,000 2,000 0.024 0.035 36,000 1,500 0.020 0.032 36,000 1,300 0.015 0.025 35,000 1,000

0.6 R 3 0.020 0.040 35,000 1,800 0.020 0.030 35,000 1,100 0.150 0.030 35,000 1,000 0.012 0.025 32,000 900

5 0.020 0.035 28,000 1,400 0.018 0.033 26,000 900 0.018 0.030 26,000 800 0.018 0.025 24,000 700

2 0.025 0.040 38,000 3,000 0.025 0.040 35,000 1,100 0.025 0.030 35,000 1,000 0.020 0.030 32,000 900

0.75 R 4 0.025 0.030 35,000 2,700 0.025 0.030 33,000 1,000 0.020 0.030 30,000 900 0.020 0.025 27,000 800

6 0.020 0.030 30,000 2,200 0.020 0.025 30,000 900 0.020 0.020 26,000 800 0.020 0.020 24,000 700

3 0.030 0.050 35,000 2,200 0.020 0.040 35,000 1,200 0.020 0.035 35,000 1.000 0.020 0.030 32,000 900

1.0 R 5 0.030 0.050 32,000 1,900 0.020 0.035 32,000 1,000 0.020 0.030 32,000 900 0.020 0.030 30,000 800

10 0.020 0.035 24,000 900 0.015 0.030 20,000 700 0.015 0.025 20,000 600 0.015 0.020 16,000 450

1.5 R 6 0.040 0.050 30,000 1,400 0.030 0.040 28,000 1,100 0.033 0.040 28,000 1,000 0.033 0.040 22,000 760

8 0.035 0.060 28,000 1,200 0.030 0.040 25,000 1,000 0.030 0.040 25,000 900 0.030 0.040 20,000 660

2.0 R 12 0.040 0.060 30,000 2,400 0.030 0.050 28,000 1,400 0.030 0.050 25,000 1,200 0.030 0.040 20,000 1,000

16 0.030 0.050 24,000 1,800 0.030 0.040 22,000 1,000 0.030 0.040 20,000 800 0.020 0.040 16,000 750

*. Air blow 공급 조건입니다.

*. CBN 의 내열 온도는 1,100°c 입니다.

*. 작업 현장의 소리를 담아, 자료의 보완을 계속 하겠습니다.

- 22-