Page 32 - samyoung

P. 32

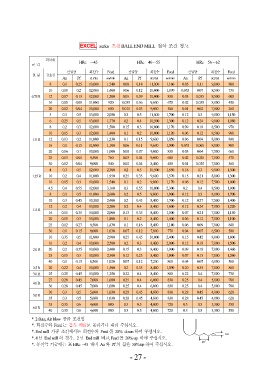

EXCEL series 초경 BALLEND MILL 절삭 조건 참고

피삭재 HRc ~ 45 HRc 46 ~ 55 HRc 56 ~ 62

규격

R 값 유효장 절입량 회전수 Feed 절입량 회전수 Feed 절입량 회전수 Feed

0.75 R 8 Aa Pf R.P.M ㎜/min Aa Pf R.P.M ㎜/min Aa Pf R.P.M ㎜/min

10 0.1 0.25 0.08 0.18 0.05 0.11

1.0 R 12 0.08 0.2 13,000 1.540 0.06 0.12 11,000 1.160 0.035 0.07 9,000 800

16 0.07 0.13 12,000 1,400 0.05 0.09 10,000 1,070 0.03 0.055 8,500 730

1.25 R 20 0.05 0.08 12,000 1,200 0.035 0.06 10,000 830 0.02 0.035 8,500 600

3 0.02 0.04 11,000 920 0.015 0.03 9,600 670 0.01 0.02 8,000 450

1.5 R 6 0.3 0.5 10,000 600 0.2 0.5 9,000 380 0.12 0.3 7,500 260

8 0.25 0.5 13,000 2,080 0.2 0.4 11,000 1,700 0.12 0.24 9,000 1,150

2.0 R 10 0.2 0.3 13,000 1,770 0.15 0.3 10,500 1,300 0.09 0.18 9,000 1,080

2.5 R 12 0.15 0.3 12,000 1,500 0.1 0.2 10,000 1,170 0.06 0.12 8,500 970

3.0 R 16 0.13 0.2 12,000 1,400 0.1 0.15 10,000 1,120 0.06 0.09 8,500 900

4.0 R 20 0.1 0.15 11,000 1,230 0.06 0.11 9,600 1,050 0.035 0.065 8,000 840

5.0 R 25 0.06 0.1 11,000 1,100 0.05 0.07 9,600 1,000 0.03 0.04 8,000 800

6.0 R 30 0.03 0.05 10,000 1,000 0.03 0.04 9,000 830 0.02 0.025 7,500 660

4 0.02 0.04 9,500 760 0.02 0.04 9,000 680 0.01 0.025 7,500 570

10 0.3 0.5 9,000 540 0.2 0.5 8,400 480 0.18 0.3 7,000 360

16 0.2 0.4 12,000 2,300 0.25 0.35 10,500 1,850 0.15 0.21 9,000 1,500

4.5 0.15 0.3 11,000 1,950 0.1 0.2 9,600 1,570 0.06 0.12 8,000 1,300

8 0.4 0.55 10,000 1,540 0.3 0.55 9,000 1,170 0.2 0.4 7,500 1,000

10 0.3 0.5 12,000 3,160 0.2 0.5 10,000 2,300 0.12 0.3 8,500 1,900

12 0.3 0.45 11,000 2,600 0.2 0.45 9,000 1,900 0.12 0.27 8,000 1,700

16 0.2 0.4 10,500 2,400 0.2 0.4 8,400 1,700 0.12 0.24 7,500 1,400

20 0.15 0.35 10,000 2,200 0.13 0.35 8,400 1,600 0.07 0.21 7,000 1,220

25 0.15 0.3 10,000 2,000 0.1 0.2 8,400 1,500 0.06 0.12 7,000 1,150

30 0.12 0.27 10,000 1,800 0.1 0.16 8,400 1,400 0.06 0.09 7,000 1,100

10 0.1 0.15 9,500 1,430 0.07 0.12 8,400 1,140 0.04 0.07 7,000 840

16 0.35 0.5 9,000 1,030 0.25 0.45 7,800 770 0.15 0.42 6,500 580

20 0.2 0.4 11,000 2,900 0.2 0.3 10,000 2,400 0.12 0.18 8,000 1,800

25 0.2 0.35 10,000 2,500 0.15 0.3 8,400 2,000 0.09 0.18 7,000 1,500

40 0.15 0.3 10,000 2,400 0.12 0.25 8,400 1,900 0.07 0.15 7,000 1,460

20 0.1 0.15 10,000 2,300 0.07 0.12 8,400 1,800 0.04 0.07 7,000 1,260

25 0.22 0.4 8,500 1,020 0.2 0.35 7,200 800 0.20 0.35 6,000 560

27 0.25 0.45 10,000 1,500 0.22 0.4 8,400 1,090 0.22 0.4 7,000 860

30 0.28 0.45 10,000 1,250 0.25 0.4 8,400 880 0.25 0.4 7,000 730

30 0.28 0.45 7,000 1,080 0.25 0.4 6,000 830 0.25 0.4 5,000 700

35 0.3 0.5 7,000 1,080 0.28 0.45 6,000 830 0.28 0.45 5,000 700

35 0.3 0.5 5,600 1,030 0.28 0.45 4,800 830 0.28 0.45 4,000 620

40 0.35 0.6 5,600 1,030 0.3 0.5 4,800 830 0.3 0.5 4,000 620

0.35 0.6 4,600 880 0.3 0.5 4,000 720 0.3 0.5 3,300 550

4,600 880 4,000 720 3,300 550

*. 2 flute,Air blow 공급 조건임 Aa

*. 회전수와 Feed 는 같은 비율로 올리거나 내려 주십시오. Pf

*. End mill 가공 조건에서는 회전수와 Feed 를 20% down 하여 주십시오.

*. 4 날 End mill 의 경우, 2 날 End mill 비교, Feed 를 20% up 하여 주십시오.

*. 동전극 가공에는 표 HRc ~45 대비 Aa 와 Pf 의 값을 50% up 하여 주십시오.

- 27 -