Page 39 - pointtec

P. 39

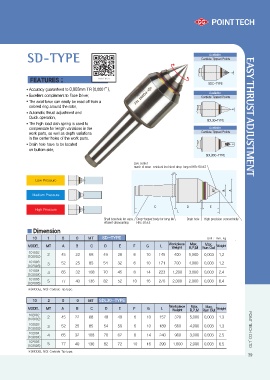

SD-TYPE Available EASY THRUST ADJUSTMENT

Carbide Tipped Points

FEATURES ; SDC-TYPE GG G

Available

• Accuracy guaranteed to 0.003mm TIR (0.0001”). Carbide Tipped Points

• Excellent complement to Face Driver.

• The axial force can easily be read off from a SDL30-TYPE

Available

colored ring around the rotor.

• Automatic thrust adjustment and Carbide Tipped Points

Quick operation. SDL30C-TYPE

• The high load dish spring is used to Live center

made of wear-resistant tool steel drop-forged HRc 60±2

compensate for length variations in the

work parts, as well as depth variations F

in the center holes of the work parts.

• Drain hole have to be located

on buttom side.

Low Pressure

B

A

Medium Pressure

High Pressure C DE

L

Shaft borehole for easy Drop-forged body for long life Drain hole High precision concentricity

effcient dismounting HRc 50±2

Dimension

10 1 0 0 MT SD-TYPE Unit : mm, kg

B CD E

MODEL MT A F G L Workpiece Max, Max, Weight

Weight R.P.M Run Out

101002 2 45 22 68 49 28 6 10 145 400 5,000 0.003 1.2

(102002) 3 52

4 65 25 85 54 32 6 10 171 700 4,000 0.003 1.2

101003 5 77

(102003) 32 108 70 45 8 14 223 1,200 3,000 0.003 2.4

101004 40 136 82 52 10 16 270 2,000 2,000 0.003 6.4

(102004)

101005

(102005)

※(MODEL NO):Carbide Tip type.

10 2 0 0 MT SDL30-TYPE

C DE

MODEL MT A B 68 49 49 F G L Workpiece Max, RuMnaOx,ut Weight

85 54 50 6 Weight R.P.M

108 70 62 6 POINT TECH CO.,LTD

102002 2 45 22 136 82 72 8 10 157 320 5,000 0.003 1.3

(103002) 10

102003 3 52 25 10 189 560 4,000 0.003 1.3

(103003) 4 65 32

5 77 40 14 240 960 3,000 0.003 2.5

102004

(103004) 16 290 1,600 2,000 0.003 6.5

102005

(103005)

※(MODEL NO):Carbide Tip type. 39