Page 237 - jjtools

P. 237

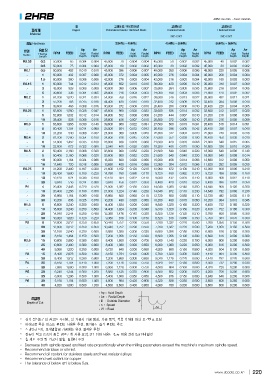

2HRB RPM : rev./min Feed : mm/min

Copper Prehardened Steels / Hardened Steels Hardened Steels Hardened Steels

SKD / SKT SKD / SKT

Material

Hardness 30HRc ~ 45HRc 45HRc ~ 55HRc 55HRc ~ 65HRc

Radius Effective RPM FEED Ap Ae RPM FEED Ap Ae RPM FEED Ap Ae RPM FEED Ap Ae

R0.05 Length

R0.1 Axial Radial Axial Radial Axial Radial Axial Radial

R0.15 0.3 Depth Depth Depth Depth Depth Depth Depth Depth

R0.2 0.5

R0.25 0.5 50,000 85 0.004 0.004 45,000 70 0.004 0.004 45,000 50 0.002 0.002 45,000 40 0.002 0.002

R0.3 1 50,000 75 0.004 0.004 45,000 60 0.002 0.002 45,000 30 0.002 0.002 45,000 30 0.002 0.002

R0.4 1.5 50,000 492 0.010 0.010 45,000 396 0.006 0.007 45,000 260 0.006 0.006 45,000 220 0.005 0.006

R0.5 1 50,000 432 0.007 0.008 45,000 372 0.004 0.005 45,000 276 0.004 0.004 45,000 200 0.004 0.004

3 50,000 360 0.006 0.006 42,000 276 0.003 0.004 42,000 216 0.003 0.004 42,000 180 0.003 0.003

R0.75 5 50,000 744 0.012 0.013 45,000 552 0.010 0.010 38,000 420 0.090 0.010 38,000 348 0.007 0.009

1 48,000 528 0.008 0.009 40,800 360 0.006 0.007 33,600 264 0.005 0.005 33,600 216 0.004 0.005

R1 3 39,600 336 0.004 0.005 28,800 216 0.003 0.003 24,000 168 0.003 0.003 21,600 120 0.002 0.002

5 61,200 1,020 0.021 0.034 54,000 768 0.016 0.022 39,600 516 0.013 0.022 39,600 432 0.011 0.021

R1.5 1 55,200 768 0.015 0.016 44,400 480 0.010 0.010 32,400 312 0.009 0.010 32,400 264 0.008 0.010

5 39,600 468 0.008 0.016 30,000 372 0.008 0.010 26,400 288 0.006 0.010 26,400 228 0.004 0.005

R2 10 63,600 1,560 0.026 0.047 45,600 960 0.020 0.033 33,600 636 0.014 0.032 33,600 312 0.007 0.020

1 52,800 1,032 0.012 0.014 34,800 552 0.008 0.008 31,200 444 0.007 0.010 31,200 216 0.006 0.009

R2.5 5 38,400 528 0.008 0.016 28,800 456 0.007 0.010 28,800 372 0.005 0.010 27,600 216 0.005 0.009

R3 10 63,600 1,956 0.030 0.140 39,600 960 0.022 0.091 27,600 600 0.019 0.091 26,400 516 0.014 0.091

R4 2 50,400 1,104 0.014 0.068 28,800 504 0.012 0.043 26,400 396 0.008 0.042 26,400 336 0.007 0.040

R5 6 31,200 540 0.006 0.032 24,000 360 0.005 0.020 22,800 312 0.004 0.020 22,800 240 0.003 0.018

R6 10 61,200 2,280 0.054 0.160 34,800 816 0.045 0.100 27,600 552 0.038 0.100 26,400 456 0.030 0.010

2 51,600 1,452 0.035 0.100 28,800 636 0.028 0.068 21,600 420 0.020 0.068 21,600 348 0.015 0.065

5 22,800 672 0.022 0.080 468 0.020 0.050 19,200 408 0.015 0.050 16,800 336 0.010 0.050

10 50,400 2,160 0.068 0.320 2,040 900 0.052 0.220 21,600 540 0.040 0.220 18,000 540 0.008 0.140

16 50,400 2,160 0.068 0.320 33,600 900 0.052 0.220 21,600 540 0.040 0.220 18,000 540 0.008 0.014

3 30,000 1,164 0.024 0.086 33,600 600 0.020 0.056 15,000 456 0.014 0.056 13,680 312 0.008 0.050

10 17,640 720 0.018 0.086 16,320 480 0.016 0.056 12,360 384 0.012 0.056 11,520 252 0.005 0.030

18 31,200 2,400 0.167 0.320 13,680 1,152 0.120 0.210 12,960 672 0.100 0.210 12,000 600 0.090 0.210

30 26,400 1,680 0.100 0.220 21,600 780 0.080 0.170 480 0.062 0.170 456 0.050 0.160

4 12,120 624 0.030 0.160 14,760 504 0.022 0.110 9,720 432 0.020 0.110 9,720 408 0.012 0.110

10 516 0.014 0.080 12,120 456 0.012 0.050 9,600 420 0.010 0.050 9,600 396 0.010 0.050

20 9,840 2,448 0.220 0.520 1,392 0.180 0.350 9,480 1,080 0.140 0.350 9,480 900 0.120 0.350

30 26,400 2,256 0.180 0.350 9,840 1,224 0.140 0.230 14,640 972 0.110 0.230 14,640 792 0.090 0.230

6 26,400 1,164 0.090 0.165 21,000 600 0.060 0.110 14,640 600 0.055 0.110 14,640 492 0.035 0.110

10 15,960 636 0.025 0.070 21,000 480 0.020 0.050 12,720 480 0.015 0.050 12,720 384 0.015 0.045

20 10,200 3,240 0.250 0.500 15,960 1,824 0.200 0.340 10,200 1,320 0.160 0.320 10,200 732 0.160 0.320

30 16,800 3,240 0.250 0.500 10,200 1,824 0.200 0.340 9,840 1,320 0.160 0.320 6,480 732 0.160 0.300

8 16,800 2,244 0.200 0.450 14,400 1,476 0.145 0.320 9,840 1,128 0.120 0.310 6,480 660 0.080 0.300

20 14,040 1,620 0.120 0.220 14,400 816 0.100 0.150 8,520 816 0.080 0.150 5,760 384 0.070 0.300

30 10,920 3,012 0.350 0.850 12,360 1,752 0.290 0.550 8,520 1,332 0.220 0.500 5,760 1,056 0.150 0.500

40 12,600 3,012 0.350 0.850 1,752 0.290 0.550 7,200 1,332 0.220 0.500 7,200 1,056 0.150 0.500

15 12,600 2,040 0.250 0.500 9,360 1,380 0.200 0.320 7,200 1,056 0.150 0.300 7,200 816 0.130 0.300

25 11,160 1,464 0.150 0.500 10,440 1,056 0.132 0.320 6,600 1,056 0.100 0.300 6,600 816 0.090 0.300

40 2,880 0.380 0.800 10,440 1,500 0.300 0.700 6,600 1,140 0.220 0.700 6,600 900 0.200 0.650

15 8,160 2,400 0.380 0.800 1,380 0.300 0.550 6,000 1,080 0.220 0.550 6,000 816 0.200 0.500

30 10,800 1,320 0.250 0.800 8,880 840 0.200 0.550 6,000 660 0.150 0.550 6,000 504 0.130 0.500

25 10,800 2,676 0.500 1.000 7,200 1,764 0.420 0.800 4,920 1,320 0.300 0.800 4,920 864 0.300 0.800

30 1,812 0.380 0.900 8,400 1,680 0.300 0.650 5,760 1,176 0.220 0.650 4,440 792 0.220 0.600

30 9,360 1,764 0.410 1.000 8,400 1,176 0.350 0.750 5,040 912 0.180 0.600 4,440 732 0.200 0.630

35 8,400 1,680 0.380 1.000 6,720 1,128 0.300 0.750 4,920 864 0.160 0.600 4,560 720 0.200 0.600

30 8,400 1,344 0.560 1.200 8,160 1,128 0.370 0.900 4,800 852 0.200 0.670 4,320 708 0.200 0.650

40 8,160 1,296 0.500 1.000 7,200 1,080 0.350 0.850 4,800 816 0.150 0.600 4,200 648 0.200 0.600

7,680 1,104 0.650 1.400 7,200 984 0.420 0.900 4,560 828 0.250 0.600 3,840 600 0.250 0.600

6,240 1,080 0.600 1.200 6,960 9,600 0.400 0.850 4,320 780 0.200 0.600 3,600 600 0.200 0.600

6,000 5,880 4,080 3,600

5,160 5,400

4,920 4,800

4,560

Depth of Cut Ap Axial Depth

Ae Radial Depth

D Outside Diameter

n Speed

Vf Feed

Decrease both spindle speed and feed rate proportionally when the milling parameters exceed the machine's maximum spindle speed. 220

Recommend air blow or oil mist.

Recommend oil coolant for stainless steels and heat resistant alloys.

Recommend wet collant for copper

The tolerance of below 1 is below 5 .

www.jjtools.co.kr