Page 238 - jjtools

P. 238

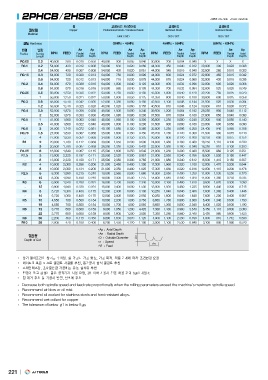

2PHCB / 2HSB / 2HCB RPM : rev./min Feed : mm/min

Copper Prehardened Steels / Hardened Steels Hardened Steels Hardened Steels

Material NAK / SKD SKD / SKT SKD / SKT

Hardness

30HRc ~ 45HRc 45HRc ~ 55HRc 55HRc ~ 65HRc

Radius Cutting RPM FEED Ae Ap RPM FEED Ae Ap RPM FEED Ae Ap RPM FEED Ae Ap

R0.05 Length

R0.1 Radial Axial Radial Axial Radial Axial Radial Axial

R0.15 0.2 Depth Depth Depth Depth Depth Depth Depth Depth

R0.2 0.2

R0.25 0.4 40,000 300 0.010 0.050 40,000 300 0.005 0.040 30,000 200 0.004 0.040 X X X X

R0.3 0.3 54,000 430 0.012 0.008 54,000 630 0.020 0.060 44,300 450 0.040 0.012 30,000 300 0.023 0.008

R0.4 0.6 54,000 430 0.007 0.008 54,000 430 0.020 0.051 44,300 345 0.016 0.040 32,800 260 0.010 0.023

R0.5 0.4 54,000 720 0.020 0.013 54,000 750 0.030 0.090 44,300 600 0.024 0.072 32,800 450 0.015 0.042

R0.6 0.8 54,000 720 0.012 0.013 54,000 715 0.030 0.075 44,300 575 0.024 0.060 32,800 430 0.015 0.035

R0.75 0.5 54,000 870 0.028 0.016 54,000 1,000 0.040 0.120 44,300 800 0.032 0.096 32,800 600 0.020 0.056

1 54,000 870 0.016 0.016 54,000 880 0.040 0.105 44,300 700 0.032 0.084 32,800 525 0.020 0.049

R1 0.6 56,000 1,250 0.035 0.022 53,000 1,250 0.050 0.150 43,500 1,000 0.040 0.120 32,200 750 0.025 0.070

R1.25 1.2 56,000 1,250 0.021 0.022 50,000 1,000 0.050 0.125 41,350 800 0.040 0.100 30,600 600 0.025 0.058

R1.5 0.8 58,000 1,510 0.042 0.026 52,000 1,380 0.060 0.180 42,650 1,100 0.048 0.144 31,500 825 0.030 0.084

2 58,000 1,510 0.025 0.026 48,500 1,020 0.060 0.155 40,500 810 0.048 0.124 30,000 610 0.030 0.072

R2 1 52,000 1,870 0.056 0.036 48,000 1,500 0.080 0.240 39,500 1,200 0.064 0.192 29,250 900 0.040 0.112

R2.5 2.5 52,000 1,870 0.033 0.036 45,000 1,085 0.080 0.200 37,500 870 0.064 0.160 27,800 650 0.040 0.093

R3 3 41,000 1,660 0.063 0.040 45,000 1,560 0.100 0.300 36,900 1,250 0.080 0.240 27,300 940 0.050 0.140

R4 1.5 41,000 1,660 0.022 0.040 40,000 1,000 0.100 0.200 31,500 800 0.080 0.160 23,000 600 0.050 0.090

R5 4 34,000 1,740 0.072 0.051 40,100 1,550 0.120 0.360 32,800 1,250 0.096 0.288 24,400 940 0.060 0.168

R6 2 27,000 1,830 0.087 0.068 35,000 1,600 0.150 0.450 28,700 1,280 0.120 0.360 21,500 960 0.075 0.210

R8 5 27,000 1,830 0.052 0.068 34,000 1,000 0.150 0.325 26,000 800 0.120 0.260 19,250 600 0.075 0.152

R10 6 20,000 1,780 0.112 0.089 30,000 1,850 0.200 0.600 24,600 1,480 0.160 0.480 18,250 1,110 0.100 0.280

3 20,000 1,780 0.067 0.089 26,500 1,350 0.200 0.435 22,000 1,080 0.160 0.348 16,250 810 0.100 0.203

8 16,000 1,840 0.067 0.115 25,500 1,600 0.250 0.542 21,000 1,280 0.200 0.430 15,500 960 0.125 0.251

4 13,000 2,220 0.197 0.171 25,500 2,520 0.300 0.957 21,000 2,050 0.240 0.766 15,500 1,530 0.150 0.447

8 13,000 2,220 0.100 0.171 25,500 2,350 0.300 0.765 21,000 1,880 0.240 0.612 15,500 1,410 0.150 0.357

5 10,000 2,080 0.266 0.208 21,000 2,450 0.400 1.380 17,300 1,960 0.320 1.100 12,800 1,470 0.200 0.644

10 10,000 2,080 0.134 0.208 21,000 2,350 0.400 1.020 17,300 1,880 0.320 0.816 12,800 1,410 0.200 0.476

6 1,990 0.215 0.240 18,000 2,560 0.500 1.660 14,800 2,050 0.400 1.330 11,000 1,530 0.250 0.770

12 8,300 1,990 0.180 0.240 18,000 2,300 0.500 1.275 14,800 1,840 0.400 1.020 11,000 1,380 0.250 0.595

8 8,300 1,940 0.290 0.281 16,000 2,700 0.600 2.340 13,000 2,160 0.480 1.870 1,620 0.300 1.090

14 6,900 1,940 0.230 0.281 16,000 2,400 0.600 1.530 13,000 1,920 0.480 1.225 9,600 1,440 0.300 0.715

10 6,900 1,000 0.400 0.175 12,500 2,300 0.800 3.100 10,250 1,840 0.640 2.480 9,600 1,380 0.400 1.446

18 5,720 1,000 0.400 0.175 12,500 2,000 0.800 2.050 10,250 1,600 0.640 1.640 7,600 1,200 0.400 0.957

12 5,720 700 0.500 0.154 10,500 2,200 1.000 3.750 1,780 0.800 3.000 7,600 1,340 0.500 1.750

22 4,550 700 0.500 0.154 10,500 1,700 1.000 2.550 8,650 1,360 0.800 2.040 6,400 1,020 0.500 1.190

30 4,550 600 0.600 0.159 1,850 1.200 4.420 8,650 1,480 0.960 3.540 6,400 1,110 0.600 2.060

38 3,770 600 0.600 0.159 9,000 1,600 1.200 3.050 7,380 1,280 0.960 2.440 5,450 960 0.600 1.423

3,770 460 0.115 0.450 9,000 1,630 3.870 1.120 7,380 1,100 2.350 0.790 5,450 810 1.742 0.500

2,200 470 0.100 0.400 6,800 1,450 4.120 1.100 4,900 1,100 2.530 0.840 4,000 800 1.866 0.520

2,000 6,200 3,900 3,100

Depth of Cut Ap Axial Depth

Ae Radial Depth

D Outside Diameter

n Speed

Vf Feed

Decrease both spindle speed and feed rate proportionally when the milling parameters exceed the machine's maximum spindle speed.

Recommend air blow or oil mist.

Recommend oil coolant for stainless steels and heat resistant alloys.

Recommend wet collant for copper

The tolerance of below 1 is below 5 .

221 JJ TOOLS