Page 242 - jjtools

P. 242

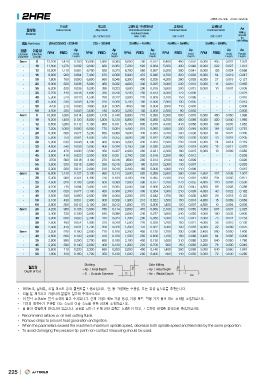

2HRE RPM : rev./min Feed : mm/min

Material Carbon Steels Alloy Steels Prehardened Steels / Hardened Steels Hardened Steels Ae

Hardness SK / SCM / SUS Hardened Steels SKD / SKT SKD / SKT

(S45C/S50C) ~225HB NAK / SKD Milling

225 ~ 325HB 45HRc ~ 55HRc 55HRc ~ 60HRc amount

35HRc ~ 45HRc

for

side Milling

Outside Effective RPM FEED Ap RPM FEED Ap RPM FEED Ap RPM FEED Ap RPM FEED Ap Ae

Diameter Length

13,200 1,470 Axial 1,080 Axial 8,000 700 Axial 6,400 480 Axial 8,000 435 Axial Radial

3mm 6 11,600 1,270 Depth 930 Depth 7,200 620 Depth 5,800 430 Depth 8,000 222 Depth Depth

10 10,500 1,110 830 6,700 560 5,300 380 8,000 128

4mm 12 0.103 10,900 670 0.093 5,900 470 0.072 4,700 320 0.052 8,000 54 0.031 1.978

16 8,900 900 0.092 9,600 560 0.083 5,300 400 0.064 4,300 280 0.046 8,000 27 0.027 1.013

5mm 20 7,800 750 0.081 8,700 460 0.073 4,800 340 0.057 3,900 230 0.041 8,000 14 0.024 0.586

25 6,900 620 0.064 7,400 390 0.058 4,500 290 0.045 3,600 200 0.032 8,000 10 0.019 0.247

6mm 30 6,200 520 0.050 6,600 330 0.045 4,200 250 0.035 3,300 170 0.025 0.015 0.127

8mm 35 5,700 440 0.036 5,800 280 0.032 3,900 220 0.025 3,100 150 0.018 - - 0.010 0.065

40 5,300 370 0.026 5,200 230 0.023 3,700 180 0.018 2,900 130 0.013 - - 0.007 0.038

45 5,000 330 0.018 4,800 200 0.016 3600 160 0.013 2800 110 0.009 - - 0.024

50 4700 270 0.013 4,500 180 0.012 3,200 130 0.009 2,500 0.006 - - - 0.016

60 4,500 250 0.008 4,200 0.008 6,800 770 0.006 5,300 90 0.005 - - - 0.012

8 10,000 1,600 0.006 3900 1,100 0.005 5,900 690 0.004 4,700 500 0.003 6,000 450 - 0.008

10 9,200 1,400 0.003 3,600 1,000 0.003 5,100 600 0.003 4,100 460 0.002 6,000 420 - 0.005

12 8,500 1,280 0.014 8,800 0.140 4,400 510 0.093 3,600 410 0.070 6,000 388 - 1.990

16 7,200 1,050 0.120 8,000 950 0.120 4,000 440 0.085 3,200 350 0.066 6,000 164 0.050 1.960

20 6,300 880 0.112 7,100 770 0.101 3,600 380 0.078 2,900 300 0.056 6,000 84 0.040 1.852

25 5,600 750 0.093 6,000 650 0.084 3,300 330 0.065 2,600 260 0.046 6,000 43 0.033 0.781

30 5,000 630 0.077 5,200 540 0.069 3,100 290 0.054 2,500 230 0.038 6,000 24 0.027 0.400

35 4,600 540 0.061 4,600 460 0.055 2,900 250 0.042 2,300 200 0.030 6,000 15 0.022 0.205

40 4,200 470 0.048 4,100 400 0.043 2,700 230 0.033 2,200 180 0.024 6,000 10 0.018 0.119

45 3,900 410 0.038 3,800 350 0.034 2600 200 0.026 2100 160 0.019 - - 0.014 0.075

50 3700 360 0.030 3,500 300 0.027 2,500 180 0.021 2,000 140 0.015 - - 0.011 0.050

55 3,500 320 0.023 3,300 270 0.021 2,400 160 0.016 1,900 130 0.012 - - 0.009 0.035

60 3,300 280 0.018 3100 250 0.016 3,500 520 0.013 2,800 110 0.009 - - - 0.026

16 6,000 1,140 0.015 2,950 210 0.015 3,100 440 0.010 2,500 360 0.007 4,800 457 - 0.020

20 5,300 980 0.011 2,800 860 0.010 2,800 390 0.008 2,200 310 0.006 4,800 234 - 0.015

25 4,600 820 0.127 5,100 730 0.114 2,500 340 0.089 2,000 270 0.064 4,800 120 - 1.907

30 4,200 710 0.121 4,400 600 0.109 2,300 300 0.085 1,900 230 0.061 4,800 69 0.038 0.977

35 3,800 620 0.109 3,800 510 0.099 2,200 270 0.077 1,700 210 0.055 4,800 43 0.036 0.500

40 3,500 540 0.094 3,400 450 0.085 1,900 210 0.066 1,500 180 0.047 4,800 29 0.033 0.289

50 3,100 430 0.077 3,100 390 0.069 1,800 170 0.054 1,400 150 0.038 4,800 15 0.028 0.182

60 2,800 350 0.060 2,800 300 0.054 2,600 470 0.042 2,100 120 0.030 4,800 10 0.022 0.122

20 4,200 960 0.031 2,400 240 0.028 2,000 340 0.022 1,600 330 0.016 4,000 607 0.018 0.063

30 3,400 730 0.013 2,100 780 0.012 1,700 260 0.009 1,300 240 0.007 4,000 180 0.009 0.036

40 3,000 600 0.126 3,800 540 0.114 1,500 220 0.088 1,200 170 0.063 4,000 75 0.004 2.025

50 2,600 480 0.109 2,800 410 0.099 1,300 170 0.077 1,000 160 0.055 4,000 38 0.037 0.600

60 2,400 410 0.083 2,300 310 0.074 2,300 450 0.058 1,700 120 0.041 4,000 22 0.033 0.253

20 3,200 910 0.054 1,900 260 0.049 1,500 250 0.038 1,100 330 0.027 3,400 580 0.024 0.130

40 2,600 600 0.031 1,700 710 0.028 2,100 430 0.022 1,500 160 0.016 3,400 84 0.016 0.075

25 2,900 890 0.180 2,800 410 0.160 1,300 220 0.130 310 0.090 3,200 540 0.009 1.600

45 2,200 580 0.120 2,000 680 0.100 2,000 400 0.800 900 150 0.060 3,200 76 0.050 0.200

30 2,500 710 0.200 2,700 400 0.180 1,500 200 0.130 1,400 280 0.080 3,000 540 0.035 1.760

50 1,900 420 0.140 2,000 580 0.120 0.700 140 0.050 3,000 72 0.050 0.240

0.220 2,300 350 0.200 0.140 800 0.080 0.030 1.840

0.160 1,700 0.130 0.800 0.050 0.050 0.280

0.030

Depth of Cut Slotting Side Milling

Ap Axial Depth Ap Axial Depth

D Outside Diameter Ae Radial Depth

Recommend airblow or oil mist cutting fluids.

Remove chips to prevent heat generation and ignition.

When the parameters exceed the machine's maximum spindle speed, decrease both spindle speed and feed rate by the same proportion.

To avoid damaging the precision tip point non-contact measuring should be used.

225 JJ TOOLS