Page 281 - jjtools

P. 281

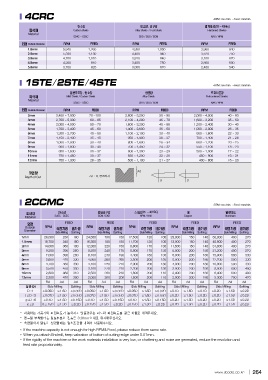

4CRC RPM : rev./min Feed : mm/min

Material Carbon Steels Alloy Steels / Tool Steels (35 ~ 45Hrc)

S54C ~ S55C SKD / SUS / SCM Hardened Steelss

Outside Diameter

1.9mm NAK / HPM

2.9mm

3.9mm RPM FEED RPM FEED RPM FEED

4.9mm

5.9mm 5,940 1,260 4,950 1,050 3,960 840

5,280 1,130 4,400 940 3,520 750

4,700 1,010 3,910 840 3,100 670

4,200 3,400 750 2,800 600

3,700 910 3,000 670 2,400 540

820

1STE / 2STE / 4STE RPM : rev./min Feed : mm/min

Material Mild Steels / Carbon Steels Alloy Steels Prehardened Steelss

S54C ~ S55C SKD / SUS / SCM NAK / HPM

Outside Diameter

RPM FEED RPM FEED RPM FEED

2mm

3mm 3,400 ~ 7,000 70 ~100 2,600 ~ 5,200 50 ~ 90 2,000 ~ 4,000 40 ~ 60

4mm 2,700 ~ 5,300 60 ~ 85 2,100 ~ 4,200 45 ~ 70 1,600 ~ 3,200 35 ~ 50

5mm 2,000 ~ 4,000 50 ~ 70 1,600 ~ 3,200 40 ~ 55 1,200 ~ 2,400 30 ~ 40

6mm 1,700 ~ 3,400 45 ~ 60 1,400 ~ 2,600 35 ~ 50 1,000 ~ 2,000 26 ~ 35

7mm 1,300 ~ 2,700 40 ~ 50 1,100 ~ 2,100 30 ~ 40 22 ~ 30

8mm 1,150 ~ 2,400 35 ~ 45 28 ~ 37 800 ~ 1,600 21 ~ 28

9mm 1,000 ~ 2,000 30 ~ 40 950 ~ 1,900 26 ~ 34 700 ~ 1,400 20 ~ 25

10mm 30 ~ 40 800 ~ 1,600 24 ~ 32 600 ~ 1,200 18 ~ 23

11mm 900 ~ 1,800 30 ~ 37 700 ~ 1,450 23 ~ 29 550 ~ 1,100 17 ~ 22

12mm 800 ~ 1,600 30 ~ 37 600 ~ 1,300 22 ~ 28 500 ~ 1,000 16 ~ 21

750 ~ 1,450 28 ~ 35 550 ~ 1,200 21 ~ 27 16 ~ 20

700 ~ 1,300 500 ~ 1,100 450 ~ 900

400 ~ 800

Depth of Cut

2CCMC RPM : rev./min Feed : mm/min

Material S45C - S55C SCM / SKD (35 40HRC) Copper Aluminum

HPM / NAK

Outside

Diameter FEED FEED FEED FEED FEED

1mm RPM RPM RPM RPM RPM

1.5mm

2mm Side Milling Soltting Side Milling Soltting Side Milling Soltting Side Milling Soltting Side Milling Soltting

3mm

4mm 28,000 230 180 24,500 180 150 17,500 120 100 23,000 150 140 50,000 400 270

5mm

6mm 18,700 340 180 16,300 180 150 11,700 120 100 13,000 150 140 40.900 400 270

8mm

10mm 14,000 360 190 12,300 220 150 8,800 170 130 11,500 150 140 31,800 400 270

12mm

9,300 390 250 8,200 240 170 5,800 170 130 8,000 200 180 21,200 400 270

D1

D3 7,000 390 260 6,100 240 190 4,400 180 130 6,000 200 180 15,900 500 330

D6

D 5,600 470 330 4,900 260 260 3,500 200 150 5,000 200 180 12,700 500 330

4,700 480 330 4,100 270 210 2,900 200 130 4,000 200 180 10,600 500 330

3,500 470 330 3,100 270 210 2,200 200 130 3.000 200 180 8,000 600 400

2,800 480 310 2,500 280 210 1,800 200 110 2,400 200 180 6,400 600 400

2,300 470 300 2,000 260 200 1,500 200 110 2,000 200 180 5.300 700 470

Rd Ad Ad Rd Ad Ad Rd Ad Ad Rd Ad Ad Rd Ad Ad

Side Milling Soltting Side Milling Soltting Side Milling Soltting Side Milling Soltting Side Milling Soltting

0.05D 1.5D 0.02D 0.05D 1.5D 0.02D 0.05D 1.5D 0.02D 0.1D 1.5D 0.1D 0.2D 1.5D 0.2D

0.07D 1.5D 0.05D 0.07D 1.5D 0.05D 0.07D 1.5D 0.05D 0.2D 1.5D 0.2D 0.2D 1.5D 0.2D

0.1D 1.5D 0.15D 0.1D 1.5D 0.15D 0.1D 1.5D 0.15D 0.2D 1.5D 0.2D 0.2D 1.5D 0.2D

0 .15D 1.5D 0.2D 0.15D 1.5D 0.2D 0.15D 1.5D 0.2D 0.2D 1.5D 0.2D 0.2D 1.5D 0.2D

If the machine capacity is not enough for high RPM& Feed, please reduce them same rate.

When you attach Endmill, keep vabration of botton of cutting-edge under 0.01mm.

If the rigidity of the machine or the work materials installation is very low, or chattering and noise are generated, reduce the revolution and

feed rate proportionately.

www.jjtools.co.kr 264