Page 230 - jjtools

P. 230

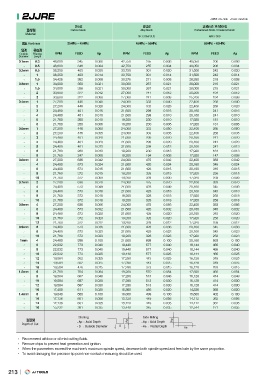

2JJRE RPM : rev./min Feed : mm/min

Carbon Steels Alloy Steels Prehardened Steels / Hardened Steels

SK / SCM/ SUS NAK / SKD

Material 35HRc ~ 45HRc

Hardness 45HRc ~ 55HRc 55HRc ~ 65HRc

Outside Effective RPM FEED Ap RPM FEED Ap RPM FEED Ap

Diameter Length

0.1mm 48,600 345 0.006 42,750 255 0.006 40,050 206 0.006

0.2mm 0.3 48,600 346 0.004 42,750 255 0.004 40,050 206 0.004

0.3mm 0.5 38,250 403 0.020 33,750 301 0.020 31,500 242 0.020

0.4mm 0.5 38,250 403 0.014 33,750 301 0.014 31,500 242 0.014

1 34,425 362 0.008 30,375 271 0.008 28,350 218 0.008

0.5mm 1.5 34,000 358 0.021 30,000 267 0.021 28,000 215 0.021

1 34,000 358 0.021 30,000 267 0.021 28,000 215 0.021

0.6mm 1.5 30,600 322 0.012 27,000 241 0.012 25,200 194 0.012

2 30,600 322 0.008 27,000 241 0.008 25,200 194 0.008

0.7mm 3 27,200 446 0.040 24,000 333 0.040 22,400 268 0.040

1 27,200 446 0.028 24,000 333 0.028 22,400 268 0.028

0.8mm 2 24,480 401 0.016 21,600 299 0.016 20,160 241 0.016

3 24,480 401 0.010 21,600 299 0.010 20,160 241 0.010

0.9mm 4 21,760 260 0.010 19,200 230 0.010 17,920 181 0.010

1mm 5 21,760 260 0.006 19,200 230 0.006 17,920 181 0.006

6 27,200 446 0.050 24,000 333 0.050 22,400 268 0.050

1.2mm 1 27,200 446 0.035 24,000 333 0.035 22,400 268 0.035

2 24,480 401 0.020 21,600 299 0.020 20,160 241 0.020

1.4mm 3 24,480 401 0.020 21,600 299 0.020 20,160 241 0.020

4 24,480 401 0.013 21,600 299 0.013 20,160 241 0.013

5 21,760 260 0.013 19,200 230 0.013 17,920 181 0.013

6 21,760 247 0.008 19,200 194 0.008 17,920 147 0.008

8 27,200 636 0.042 24,000 475 0.042 22,400 383 0.042

2 24,480 573 0.024 21,600 428 0.024 20,160 345 0.024

4 24,480 573 0.015 21,600 428 0.015 20,160 345 0.015

6 21,760 372 0.015 19,200 328 0.015 17,920 258 0.015

8 21,760 372 0.009 19,200 328 0.009 17,920 258 0.009

10 27,200 636 0.070 24,000 475 0.070 22,400 383 0.070

2 24,480 573 0.049 21,600 428 0.049 20,160 345 0.049

4 24,480 573 0.018 21,600 428 0.018 20,160 345 0.018

6 21,760 372 0.018 19,200 328 0.018 17,920 258 0.018

8 21,760 372 0.018 19,200 328 0.018 17,920 258 0.018

10 27,200 636 0.056 24,000 475 0.056 22,400 383 0.056

4 24,480 573 0.032 21,600 428 0.032 20,160 345 0.032

6 24,480 573 0.020 21,600 428 0.020 20,160 345 0.020

8 21,760 372 0.020 19,200 328 0.020 17,920 258 0.020

10 21,760 372 0.012 19,200 328 0.012 17,920 258 0.012

12 24,480 573 0.036 21,600 428 0.036 20,160 345 0.036

6 24,480 573 0.023 21,600 428 0.023 20,160 345 0.023

8 21,760 372 0.023 19,200 328 0.023 17,920 258 0.023

10 24,480 936 0.100 21,600 699 0.100 20,160 563 0.100

4 22,032 773 0.040 19,440 577 0.040 18,144 465 0.040

6 22,032 773 0.040 19,440 577 0.040 18,144 465 0.040

8 22,032 773 0.025 19,440 577 0.025 18,144 465 0.025

10 19,584 502 0.025 17,280 443 0.025 16,128 348 0.025

12 19,584 502 0.025 17,280 443 0.025 16,128 348 0.025

14 19,584 476 0.015 17,280 373 0.015 16,128 283 0.015

16 21,760 764 0.084 19,200 570 0.084 17,920 460 0.084

6 19,584 687 0.048 17,280 513 0.048 16,128 414 0.048

8 19,584 687 0.030 17,280 513 0.030 16,128 414 0.030

10 19,584 687 0.030 17,280 513 0.030 16,128 414 0.030

12 17,408 611 0.020 15,360 456 0.020 14,336 368 0.020

16 19,040 668 0.100 16,800 499 0.100 15,680 402 0.100

8 17,136 601 0.056 15,120 449 0.056 14,112 362 0.056

10 17,136 601 0.035 15,120 449 0.035 14,112 362 0.035

14 15,232 391 0.035 13,440 345 0.035 12,544 271 0.035

16

Depth of Cut Slotting Side Milling

Ap Axial Depth Ap Axial Depth

D Outside Diameter Ae Radial Depth

Recommend airblow or oil mist cutting fluids.

Remove chips to prevent heat generation and ignition.

When the parameters exceed the machine's maximum spindle speed, decrease both spindle speed and feed rate by the same proportion.

To avoid damaging the precision tip point non-contact measuring should be used.

213 JJ TOOLS