Page 228 - jjtools

P. 228

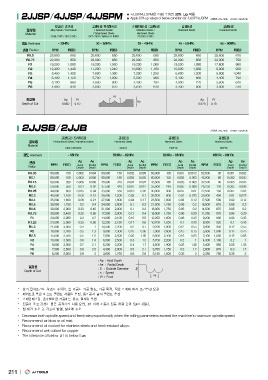

2JJSP / 4JJSP / 4JJSPM Apply 20% up values of below condition for 4JJSP/4JJSPM RPM : rev./min Feed : mm/min

Alloy Steels / Tool Steels Hardened Steels / Stainless Steels / Hardened Steels Hardened Steels

Prehardened Steels Hardened Steels

Material SCM / SKT / SKS / SKD SKT / SKD / NAK55 / HPM11 SUS304 / SKD

Hardness ~ 30HRc 30 ~ 38HRc 38 ~ 45HRc 45 ~ 55HRc 55 ~ 60HRc

Radius RPM FEED RPM FEED RPM FEED RPM FEED RPM FEED

R0.5

R0.75 25,600 680 25,600 680 25,600 680 25,600 680 25,600 610

R1 22,000 850 22,000 850 22,000 850 22,000 850 22,000 750

R2 19,200 1,080 19,200 1,080 19,200 1,080 19,200 1,080 17,600 960

R3 12,400 1,440 11,200 1,240 10,800 1,160 10,000 1,080 920

R4 1,480 1,360 1,280 1,200 8,800 1,040

R5 8,400 1,120 7,600 1,000 7,200 960 6,800 880 5,900 790

R6 6,400 880 5,700 800 5,500 784 5,100 720 4,400 640

5,100 840 4,600 670 4,400 640 4,000 600 3,600 540

4,800 3,800 3,640 3,400 3,000

Depth of Cut Ap Pf Ap Pf

0.05D 0.1D 0.02D 0.1D

2JJSB / 2JJB RPM : rev./min Feed : mm/min

Prehardened Steels / Hardened Steels Hardened Steels Hardened Steels Hardened Steels

Material NAK / STAVAX SKD11 HAP10 HAP72

Hardness ~ 55HRc 55HRc ~ 62HRc 62HRc ~ 65HRc 65HRc ~ 68HRc

Radius RPM FEED Ap Ae RPM FEED Ap Ae RPM FEED Ap Ae RPM FEED Ap Ae

R0.05 Axial Radial Axial Radial Axial Radial Axial Radial

R0.1 Depth Depth Depth Depth Depth Depth Depth Depth

R0.15

R0.2 60,000 150 0.002 0.004 60,000 150 0.002 0.003 60,000 100 0.001 0.0012 52,500 30 0.001 0.002

R0.25 60,000 180 0.003 0.005 60,000 180 0.002 0.003 60,000 120 0.002 0.003 45,000 60 0.002 0.003

R0.3 60,000 350 0.006 0.008 45,000 310 0.004 0.007 43,500 180 0.003 0.005 32,500 90 0.003 0.005

R0.4 50,000 500 37,500 420 0.007 0.012 35,000 240 0.005 0.008 26,250 120 0.005 0.008

R0.5 44,000 650 0.01 0.02 33,000 530 0.010 30,000 300 0.007 0.01 22,500 150 0.007

R0.6 40,000 1,100 0.015 0.04 30,000 1,200 0.02 26,500 800 0.075 20,000 400 0.01

R0.75 35,000 1,600 0.13 27,000 1,600 0.02 0.1 23,500 1,000 0.01 0.12 17,500 500 0.01 0.075

R1 30,000 1,750 0.03 0.21 24,000 2,000 0.04 21,000 1,750 0.02 0.2 16,000 875 0.02

R1.25 30,000 2,000 0.06 21,000 2,000 0.17 18,000 1,750 0.05 0.2 14,500 875 0.05 0.12

R1.5 30,000 2,450 0.4 17,000 2,000 0.1 0.3 15,000 1,750 0.05 0.29 11,250 875 0.05 0.2

R2 28,000 2,900 0.2 0.45 14,000 2,100 0.1 0.3 12,250 1,800 0.06 0.35 900 0.06 0.2

R2.5 24,500 2,950 0.23 0.55 12,250 2,150 0.12 0.4 10,700 1,850 0.08 0.45 9,200 925 0.08

R3 21,000 3,000 0.25 10,500 2,200 0.15 0.5 1,900 0.55 8,050 950 0.29

R4 18,000 3,200 0.7 2,300 0.17 0.6 9,200 2,000 0.1 0.75 6,900 1,000 0.1 0.35

R5 15,600 3,500 0.3 0.85 9,000 2,500 0.2 0.7 7,900 2,100 0.12 0.85 5,900 1,050 0.12 0.45

R6 13,000 3,500 0.35 7,800 2,500 0.25 6,800 2,200 0.15 1 5,100 1,100 0.15 0.55

3,000 1 6,500 2,200 0.25 0.95 5,700 1,900 0.15 1.35 4,300 950 0.15 0.75

Depth of Cut 9,500 2,500 0.4 1.3 5,200 2,000 0.3 1.05 4,500 1,750 1.7 3,400 875 0.85

7,500 2,000 0.5 1.5 4,300 1,750 0.4 3,750 1,500 0.2 2 2,800 750 0.2

6,200 0.5 1.8 3,600 0.5 1.3 3,150 0.25 2,350 0.25 1

0.6 2.1 0.6 1.7 1.35

0.7 2.5 2.1 0.3 0.3

0.8 2.6 0.35 0.35 1.7

0.9 3 2

Ap Axial Depth

Ae Radial Depth

D Outside Diameter

n Speed

Vf Feed

Decrease both spindle speed and feed rate proportionally when the milling parameters exceed the machine's maximum spindle speed.

Recommend air blow or oil mist.

Recommend oil coolant for stainless steels and heat resistant alloys.

Recommend wet collant for copper

The tolerance of below 1 is below 5 .

211 JJ TOOLS