Page 251 - jjtools

P. 251

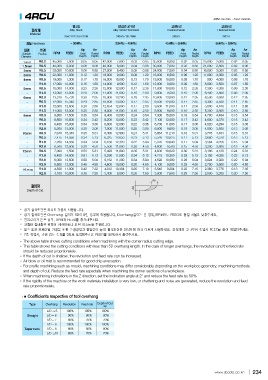

4RCU RPM : rev./min Feed : mm/min

Alloy Steels Alloy Steels/ Tool Steels Hardened Steels Hardened Steels

Material S50C / FC 250 / SCM SKD61 / SK / NAK SKD61 SKD11

Hardness

~ 30HRc 30HRc ~ 45HRc 45HRc ~ 55HRc 55HRc ~ 62HRc

Outside Radius RPM FEED Ap Ae RPM FEED Ap Ae RPM FEED Ap Ae RPM FEED Ap Ae

Diameter

1.5mm R0.2 Axial Radial Axial Radial Axial Radial Axial Radial

R0.5 Depth Depth Depth Depth Depth Depth Depth Depth

2mm R0.5

3mm R0.5 45,000 7,000 0.05 0.05 42,000 7,800 0.03 0.05 35,000 6,800 0.02 0.05 25,000 2,600 0.02 0.05

4mm R0.5 40,000 9,000 0.06 0.06 40,000 8,000 0.04 0.06 30,000 7,000 0.03 0.60 21,000 2,800 0.02 0.06

5mm R1.0 33,000 10,000 0.08 0.80 27,000 8,400 0.05 0.08 24,000 7,500 0.04 0.80 16,000 3,000 0.03 0.80

6mm R0.5 22,000 11,000 0.12 1.20 18,000 9,000 0.08 1.20 16,000 8,500 0.06 1.20 11,000 3,300 0.05 1.20

R1.0 19,000 1,300 0.17 1.70 16,000 10,000 0.13 1.70 13,000 10,000 0.09 1.70 4,000 0.08 1.70

8mm R0.3 17,000 12,000 0.15 1.50 14,000 9,500 0.12 1.50 12,000 8,800 0.08 1.50 900 3,500 0.07 1.50

R0.5 15,000 14,000 0.23 2.30 12,000 12,000 0.17 2.30 11,000 10,000 0.12 2.30 8,000 4,300 0.09 2.30

10mm R1.0 13,000 13,000 0.20 2.00 11,000 11,000 0.15 2.00 9,500 0.10 2.00 7,300 3,800 0.08 2.00

R1.5 13,310 15,730 0.30 2.95 10,900 13,200 0.18 2.95 9,600 13,000 0.12 2.95 6,400 4,600 0.12 2.95

12mm R0.3 12,980 15,340 0.29 2.85 10,600 13,000 0.17 2.85 10,000 12,000 0.11 2.85 6,500 4,500 0.11 2.85

R0.5 12,600 12,600 0.28 2.80 12,654 12,600 0.17 2.80 11,000 0.11 2.80 6,300 4,100 0.11 2.80

R1.0 11,000 13,000 0.25 2.50 11,000 0.15 2.50 9,500 9,600 0.10 2.50 5,800 3,800 0.10 2.50

R2.0 17,500 0.35 3.54 9,000 13,500 0.24 3.54 9,000 15,000 0.18 3.54 5,300 4,484 0.15 3.54

R0.3 9,800 16,500 0.34 3.42 8,400 13,000 0.23 3.42 8,000 13,000 0.17 3.42 4,700 4,370 0.15 3.42

R0.5 8,800 15,000 0.34 3.36 8,200 12,000 0.22 3.36 7,300 11,000 0.17 3.36 4,600 4,294 0.15 3.36

R1.0 8,400 13,000 0.30 3.00 8,000 11,000 0.20 3.00 7,100 9,600 0.15 3.00 4,520 3,800 0.13 3.00

R2.0 8,200 15,340 0.35 5.31 7,000 12,980 0.24 5.31 6,700 11,210 0.18 5.31 4,000 4,484 0.15 5.31

R0.5 7,670 14,950 0.34 5.13 6,490 12,650 0.23 5.13 6,000 10,925 0.17 5.13 3,776 4,370 0.15 5.13

R1.0 7,475 14,560 0.34 5.04 6,325 12,320 0.22 5.04 5,664 10,640 0.17 5.04 3,680 4,256 0.15 5.04

R2.0 7,280 13,000 0.30 4.50 6,160 11,000 0.20 4.50 5,520 9,500 0.15 4.50 3,584 3,800 0.13 4.50

R3.0 6,500 1,500 0.53 5.31 5,500 11,800 0.35 5.31 5,376 10,620 0.30 5.31 3,200 4,130 0.24 5.31

R1.0 7,000 14,000 0.51 5.13 5,428 11,500 0.34 5.13 4,800 10,350 0.29 5.13 3,186 4,025 0.23 5.13

R2.0 6,400 12,500 0.50 5.04 5,290 11,200 0.34 5.04 4,838 10,080 0.28 5.04 3,105 3,920 0.22 5.04

6,000 12,000 0.45 4.50 5,152 10,000 0.30 4.50 4,715 9,000 0.25 4.50 3,024 3,500 0.20 4.50

5,500 11,800 0.42 7.32 4,600 10,384 0.25 7.10 4,592 9,204 0.22 7.15 2,700 3,776 0.13 7.35

4,838 10,000 0.45 7.50 4,012 8,800 0.30 7.50 4,100 7,800 0.25 7.50 2,360 3,200 0.20 7.50

4,100 3,400 3,540 2,000

3,000

Depth of Cut

The above table shows cutting conditioins when machining with the corner radius cutting edge.

This table shows the cutting conditions with less than 5D overhang length. In the case of longer overhangs, the revolutioin and the feed rate

should be reduced proprtionately.

If the depth of cut is shallow, the revolution and feed rate can be increased.

Air blow or oil mist is recommended for good chip evacuation.

For profile machining such as mould, machining conditions may differ considerably depending on the workpiece geometry, machining methods

and depth of cut. Reduce the feed rate especially when machining the corner sections of a workpiece.

When machining inclinations in the Z direction, set the inclination angle at 2° and reduce the feed rate by 50%.

If the rigidity of the machine or the work materials installation is very low, or chattering and noise are generated, reduce the revolution and feed

rate proportionately.

Coefficients respective of tool overhang

Type Overhang Revolution Feed rate Depth of Cut

Straight ap

Taper neck L/D 5 100% 100%

L/D = 6 90% 80% 100%

L/D = 7 80% 70% 80%

L/D = 6 70%

L/D = 8 100% 100%

L/D 10 90% 80% 100%

80% 70% 80%

70%

www.jjtools.co.kr 234