Page 257 - jjtools

P. 257

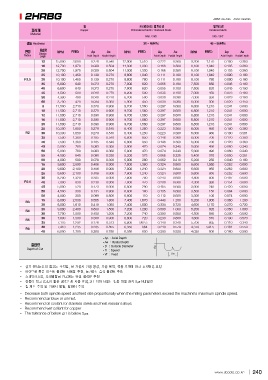

2HRBG RPM : rev./min Feed : mm/min

Copper Prehardened Steels / Hardened Steels Hardened Steels

NAK / SKD SKD / SKT

Material

Hardness 30 ~ 45HRc 45 ~ 55HRc

Effective RPM FEED Ap Ae RPM FEED Ap Ae RPM FEED Ap Ae

Length

Radius Axial Depth Radial Depth Axial Depth Radial Depth Axial Depth Radial Depth

R1.5 12

16 15,000 2,600 0.278 0.540 12,900 1,510 0.222 0.360 9,200 1,170 0.180 0.360

R2 20 12,700 1,970 0.029 0.504 11,300 1,330 0.166 0.360 8,100 1,040 0.135 0.360

25 12,700 1,970 0.029 0.504 11,300 1,330 0.166 0.360 8,100 1,040 0.135 0.360

R2.5 30 10,100 1,450 0.139 0.270 1,040 0.111 0.180 8,100 1,040 0.090 0.180

R3 35 10,100 1,450 0.139 0.270 8,800 0.111 0.180 8,100 0.090 0.180

R4 40 0.073 0.270 8,800 780 0.055 0.180 7,500 780 0.045 0.180

R5 45 6,600 840 0.073 0.270 7,900 620 0.055 0.180 7,500 650 0.045 0.180

R6 50 6,600 840 0.040 0.270 7,900 620 0.035 0.100 7,000 520 0.023 0.180

60 4,500 500 0.040 0.270 6,200 500 0.030 0.090 7,000 450 0.023 0.180

8 4,300 490 0.034 0.360 6,200 500 0.030 0.080 6,000 350 0.020 0.150

10 3,700 420 0.370 0.900 5,900 450 0.297 0.600 6,800 300 0.241 0.600

12 11,500 2,710 0.370 0.900 9,700 1,560 0.297 0.600 6,800 1,210 0.241 0.600

16 11,500 2,710 0.390 0.900 9,700 1,560 0.297 0.600 6,800 1,210 0.241 0.600

20 11,500 2,710 0.390 0.900 9,700 1,560 0.297 0.600 6,800 1,210 0.241 0.600

25 11,500 2,710 0.390 0.900 9,700 1,560 0.297 0.600 6,800 1,210 0.241 0.600

30 11,500 2,710 0.279 0.540 9,700 1,560 0.223 0.360 6,000 1,210 0.180 0.360

35 10,300 1,850 0.279 0.540 8,400 1,250 0.223 0.360 6,000 980 0.180 0.361

40 10,300 1,850 0.185 0.540 8,400 1,250 0.148 0.360 6,000 980 0.120 0.360

45 7,500 1,360 0.185 0.540 6,600 950 0.148 0.360 6,000 700 0.120 0.360

50 7,500 1,360 0.093 0.360 6,600 950 0.074 0.240 5,600 700 0.060 0.240

55 5,000 780 0.093 0.360 5,900 470 0.074 0.240 5,600 490 0.060 0.240

60 5,000 780 0.090 0.330 5,900 470 0.068 0.225 5,400 490 0.050 0.251

15 4,500 640 0.078 0.300 5,200 375 0.062 0.210 5,200 370 0.040 0.180

20 4,000 500 0.406 0.900 5,000 280 0.324 0.800 5,600 250 0.252 0.800

25 9,600 2,590 0.406 0.900 7,800 1,350 0.324 0.600 5,600 1,050 0.252 0.600

30 9,600 2,100 0.406 0.900 7,800 1,240 0.324 0.600 5,600 950 0.252 0.600

40 9,600 2,100 0.305 0.900 7,800 1,240 0.243 0.600 4,800 950 0.197 0.600

45 8,200 1,320 0.230 0.900 7,800 760 0.200 0.600 4,300 600 0.154 0.600

50 7,000 830 0.173 0.900 7,800 470 0.165 0.600 3,900 380 0.120 0.600

60 5,000 520 0.131 0.900 6,800 290 0.135 0.600 3,500 240 0.094 0.600

15 4,500 330 0.099 0.800 6,800 180 0.112 0.600 3,300 150 0.074 0.600

30 4,000 300 0.555 1.800 6,800 110 0.443 1.200 5,200 100 0.360 1.200

25 8,000 2,530 0.418 1.080 7,400 1,670 0.334 0.720 4,600 1,300 0.270 0.720

30 8,000 1,810 0.600 1.500 7,400 1,500 0.500 1.000 5,200 1,170 0.350 1.000

30 9,000 2,400 0.450 1.200 7,200 1,200 0.380 0.800 4,500 920 0.300 0.800

35 7,700 1,500 0.300 0.900 7,200 740 0.230 0.600 4,600 580 0.190 0.570

30 7,800 1,300 0.176 0.513 6,800 720 0.140 0.340 5,700 570 0.110 0.340

40 7,125 1,292 0.285 0.855 6,800 902.5 0.210 0.570 4,370 665 0.181 0.550

7,410 1,235 0.260 0.780 6,350 684 0.200 0.520 4,020 541.5 0.160 0.500

6,800 1,100 6,350 630 500

Depth of Cut Ap Axial Depth

Ae Radial Depth

D Outside Diameter

n Speed

Vf Feed

Decrease both spindle speed and feed rate proportionally when the milling parameters exceed the machine's maximum spindle speed.

Recommend air blow or oil mist.

Recommend oil coolant for stainless steels and heat resistant alloys.

Recommend wet collant for copper

The tolerance of below 1 is below 5 .

www.jjtools.co.kr 240