Page 259 - jjtools

P. 259

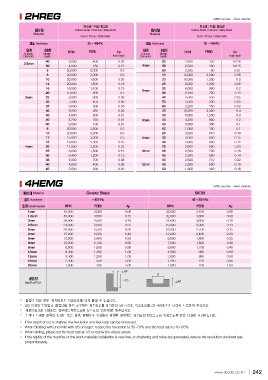

2HREG RPM : rev./min Feed : mm/min

Material Carbon Steels / Cast iron / Alloy Steels Material Carbon Steels / Cast iron / Alloy Steels

Hardness S50C / FC250 / SCM / NAK Hardness S50C / FC250 / SCM / NAK

35 ~ 45HRc 35 ~ 45HRc

Outside Effective RPM FEED Ap Outside Effective RPM FEED Ap

Diameter Length Diameter Length

2.5mm 8,000 400 Axial Depth 2,800 150 Axial Depth

40 4,000 150 4mm 50 2,500 100

3mm 50 20,000 2,000 0.03 55 2,300 0.018

6 20,000 2,000 0.15 5mm 60 12,000 80 0.015

4mm 8 20,000 1,600 15 10,000 2,500

10 20,000 1,500 0.3 6mm 20 8,000 1,200 0.01

12 15,000 1,400 0.3 8mm 25 6,000 1,000 0.35

16 10,000 800 0.25 10mm 30 5,100

20 8,000 600 0.18 12mm 35 4,000 900 0.3

25 7,000 450 0.15 40 3,000 750 0.25

30 6,000 300 0.1 50 2,200 450

35 5,000 250 0.08 60 10,000 300 0.2

40 4,500 200 0.06 20 6,000 150 0.15

45 3,700 150 0.05 30 4,200 2,000 0.05

50 3,500 100 0.02 40 3,000 1,200 0.03

60 20,000 3,500 0.01 50 1,900 800 0.02

8 20,000 3,200 0.01 60 3,200 300

10 15,000 3,000 0.01 20 3,000 150 0.4

12 13,000 2,500 0.3 30 2,600 910 0.3

16 11,000 2,200 0.3 40 2,900 800 0.2

20 8,000 1,500 0.3 25 2,500 600 0.1

25 6,400 1,200 0.25 35 2,200 890 0.1

30 5,000 700 0.22 45 2,500 700 0.18

35 4,500 400 0.15 30 2,300 580 0.15

40 3,500 300 0.12 40 1,900 710 0.12

45 0.08 50 500 0.20

0.05 420 0.16

0.03 0.14

0.22

0.18

0.16

4HEMG RPM : rev./min Feed : mm/min

Material RPM General Steels Ap RPM SKD61 Ap

0.06 0.06

Hardness 40,000 ~ 45 HRc 0.12 32,000 45 ~ 55 HRc 0.08

40,000 0.18 32,000 0.10

Outside Diameter 30,000 FEED 0.25 24,000 FEED 0.13

24,000 0.30 19,000 0.15

1mm 20,000 3,000 0.40 16,000 2,400 0.20

1.5mm 15,000 4,500 0.50 12,000 3,600 0.25

2mm 12,000 4,500 0.60 3,600 0.30

2.5mm 10,000 3,900 0.80 9,000 3,000 0.40

2mm 3,500 1.00 7,000 2,700 0.50

4mm 8,000 3,000 1.00 5,600 2,400 0.50

5mm 6,400 2,400 3.00 4,500 1,800 0.80

6mm 5,400 2,100 4.00 3,800 1,500 1.00

8mm 2,400 1,500 1,200 1,100

10mm 1,900 1,400 AP 1,000

12mm 1,200 950

16mm 1D 860

20mm 550 120

480 100

Depth of Cut AP

If the depth of cut is shallow, the revolution and feed rate can be increased.

When Slotting with end mills with 3 or larger, reduce the revolution to 50~70% and the feed rate to 40~60%.

When drilling, please set the feed rate at 1/3 or below the values above.

If the rigidity of the machine or the work materials installation is very low, or chattering and noise are generated, reduce the revolution and feed rate

proportionately.

www.jjtools.co.kr 242